Protector relays are essential components in industrial settings, ensuring the safety and efficiency of electrical systems. These devices play a critical role in protecting equipment, minimizing downtime, and optimizing energy usage. In this blog, we'll delve into the various advantages of incorporating protector relays into industrial applications.

Understanding Protector Relays

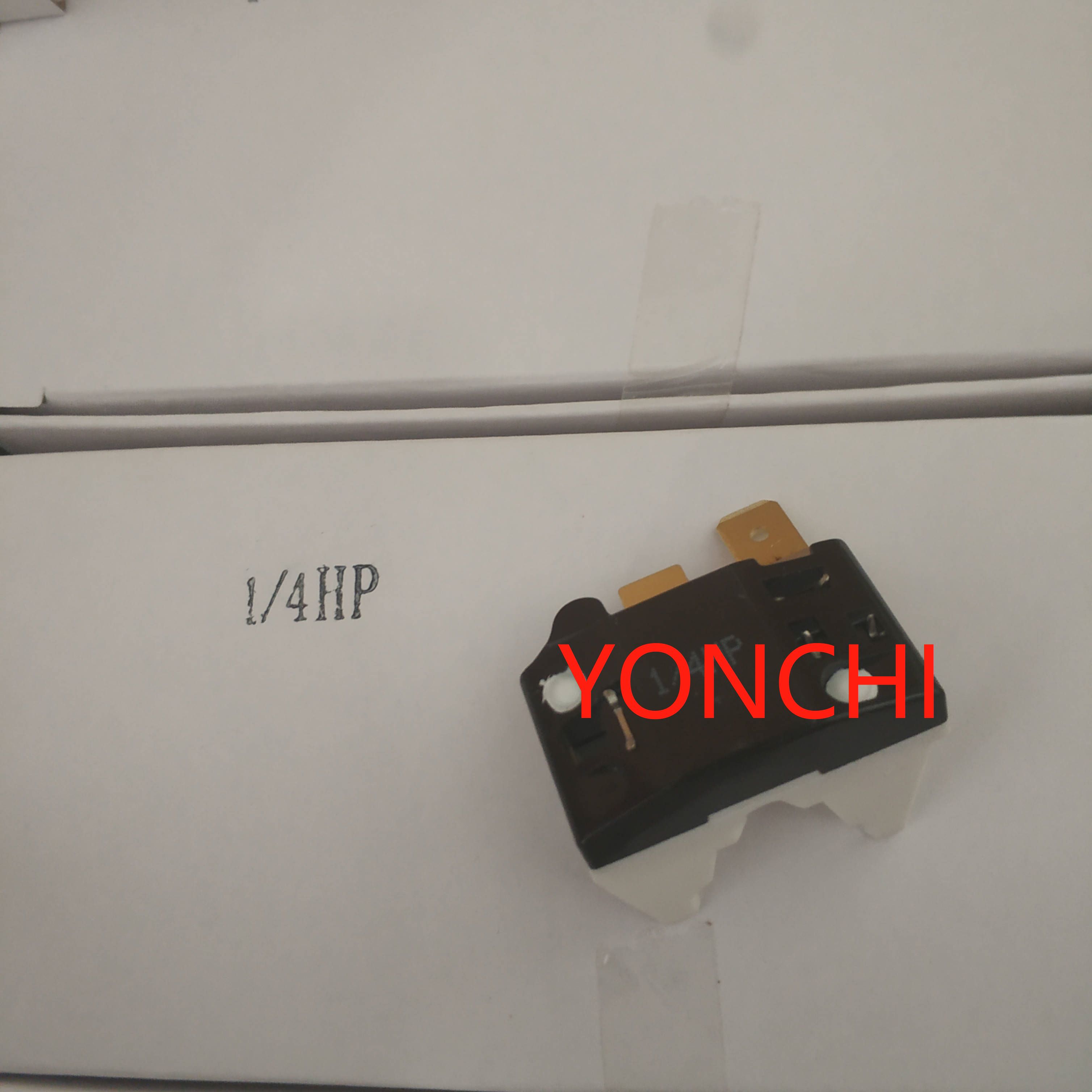

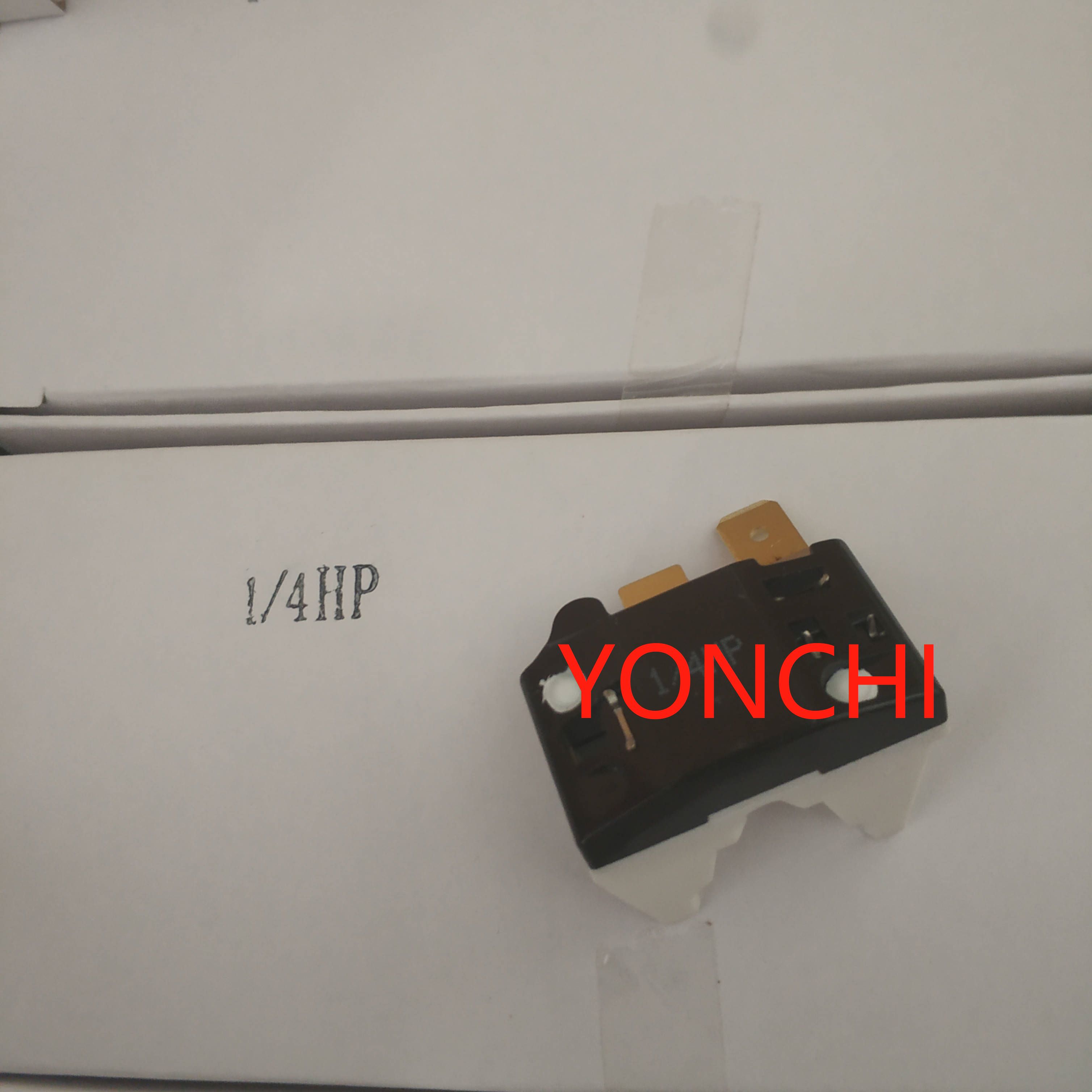

Protector relays, such as those offered by Yiwu Wisp Yun, are designed to safeguard electrical systems from faults and abnormal conditions. They consist of several key components, including sensors, processors, and actuators, which work together to monitor and control electrical circuits. The basic operation principle involves detecting anomalies and activating protective mechanisms to prevent damage.

Enhanced Safety Measures

One of the primary benefits of using protector relays in industrial applications is the enhanced safety they provide. These devices offer robust overload protection, identifying and preventing overload conditions that could otherwise lead to equipment failure or fire hazards. Case studies have demonstrated the effectiveness of protector relays in averting such risks.

Short circuit mitigation is another crucial safety feature. Protector relays employ advanced mechanisms to detect and isolate short circuits, preventing potential electrical disasters. Real-world examples highlight how these devices have successfully averted incidents that could have caused significant damage.

Arc flash prevention is equally important in industrial settings. Protector relays play a vital role in protecting against arc flashes, which can cause severe injuries and equipment damage. By employing techniques such as real-time monitoring and rapid response, these relays significantly reduce the risk of arc flash incidents.

Operational Efficiency

Protector relays contribute to improved operational efficiency by reducing downtime. They enable faster fault detection and isolation, ensuring minimal disruption to industrial processes. Examples from various industries illustrate how quick response times associated with protector relays have led to minimized operational interruptions.

In addition to reducing downtime, protector relays enhance energy management. They provide improved energy consumption monitoring, allowing for better strategies in optimizing energy usage. This results in more efficient operations and potential cost savings in the long run.

Cost Savings

Using protector relays can lead to significant cost savings in industrial applications. The advanced protection mechanisms they offer reduce the frequency of maintenance and repair, leading to lower maintenance costs. An analysis of long-term savings reveals how investing in these devices can be financially beneficial for industries.

Moreover, protector relays contribute to the prolonged lifespan of industrial equipment. By preventing damage from overloads, short circuits, and arc flashes, these devices ensure that equipment remains in good condition for longer periods. Case studies on equipment durability highlight the positive impact of protector relays on equipment longevity.

System Reliability and Stability

Protector relays enhance system reliability and stability by ensuring consistent performance. They provide a stable electrical supply, which is crucial for the smooth operation of industrial processes. Testimonials from industry leaders emphasize the reliability benefits of using protector relays.

Additionally, these devices offer improved monitoring and diagnostics capabilities. Advanced diagnostic features enable predictive maintenance, using data from relays to identify potential issues before they escalate. Examples of predictive maintenance underscore the value of protector relays in maintaining system stability.

Integration and Compatibility

Protector relays are designed for seamless integration with existing systems, making them compatible with various industrial setups. The steps for integrating protector relays into current systems are straightforward, ensuring minimal disruption during the transition.

Furthermore, protector relays help future-proof industrial operations. They are scalable and adaptable to emerging technologies, providing insights into future trends. This adaptability ensures that industries can stay ahead of technological advancements and maintain efficient operations.

Environmental Impact

Protector relays contribute to sustainable practices by reducing the carbon footprint of industrial operations. Their eco-friendly features, such as energy optimization and reduced waste, align with environmental goals. Additionally, using protector relays ensures compliance with industry standards and regulations, offering benefits of regulatory compliance.

Real-world Applications

Protector relays find applications in diverse industries, including manufacturing, energy, and transportation. Examples from these sectors demonstrate the versatility and effectiveness of these devices in various settings. Specific use cases and success stories highlight the positive impact of protector relays on industrial operations.

Insights from industry experts and feedback from companies using protector relays further emphasize their benefits. Testimonials and expert opinions provide valuable perspectives on the advantages of these devices in real-world applications.

Final Thoughts

In summary, protector relays offer numerous benefits for industrial applications, including enhanced safety, improved operational efficiency, cost savings, and increased system reliability. Industries are encouraged to adopt protector relays to enhance their operations and ensure long-term success.

For more information on protector relays and their applications, explore our comprehensive product guides and consult with our experts.