In today's highly automated society, the stability of the power system is essential. As one of the core components of electrical equipment, protective relays can not only detect abnormal conditions, but also respond quickly to prevent potential risks. They work silently like guardians, ensuring the safe operation of the entire network.

There are many types of protection relays on the market, each with its own unique purpose and application scenarios. For example, the over-current type is mainly used for motor control on industrial production lines; under-voltage detection is often used in the protection of household appliances and other fields. It is very important to choose the right model according to specific needs.

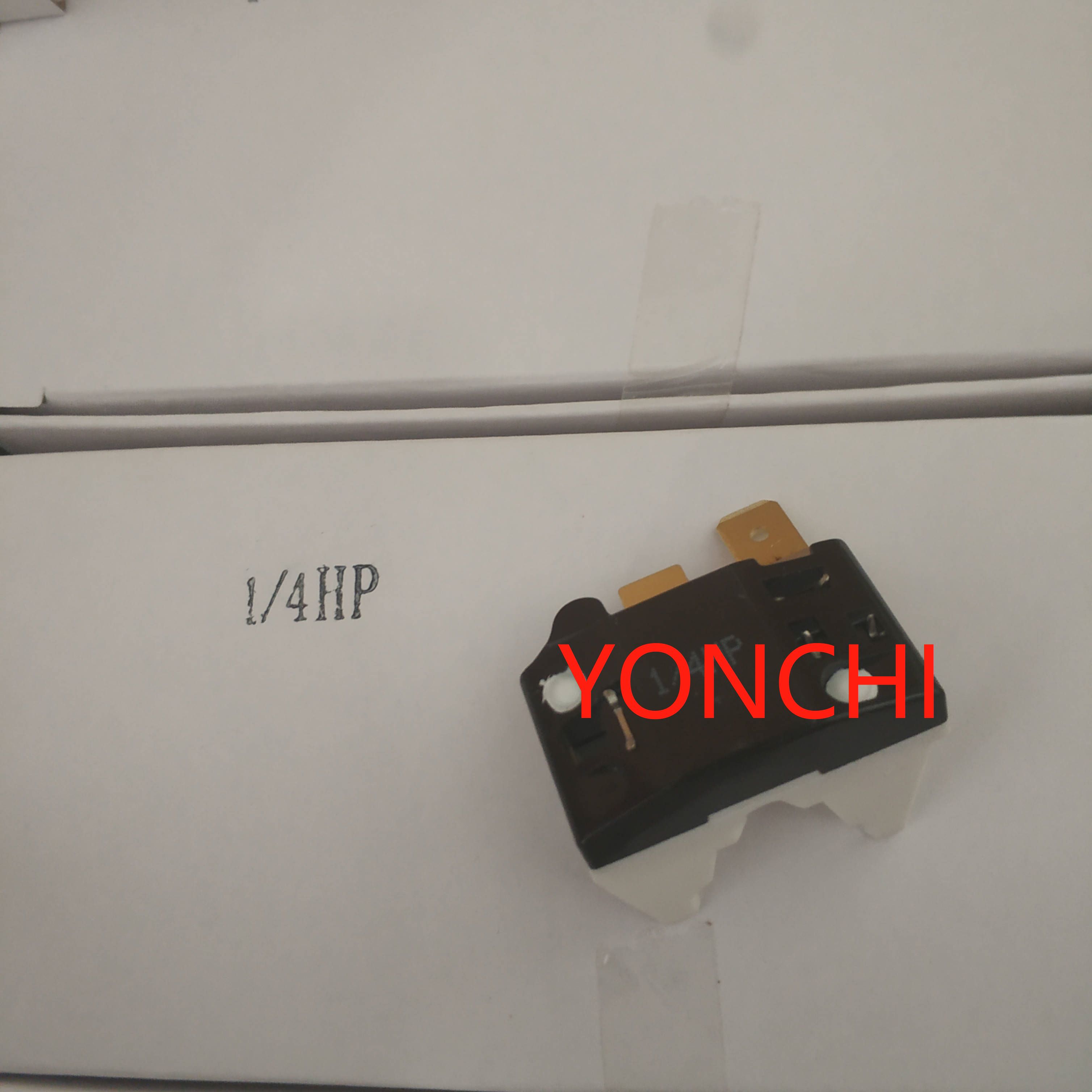

When we decide to purchase a new protective relay, we should consider several factors including but not limited to whether the rated voltage value range meets the requirements, the level of action sensitivity and the reputation of well-known brands. After all, investing in reliable and durable products is always more cost-effective and beneficial in the long run.

In fact, many industries rely heavily on high-precision and reliable devices for day-to-day operation management. The power plant avoids large-scale power outages caused by load imbalance by accurately regulating the transmission and distribution links, and the rail transit signal control system is also inseparable from the accurate switching command transmission process to ensure convenient and smooth passenger travel.

Although there are many high-quality solutions on the market to choose from, there are still some users who have serious consequences due to lack of experience. For example, ignoring the differences in test data under actual load conditions may make it impossible to normally trigger the alarm mechanism or even cause catastrophic failure events in some cases.

For first-time contacts, the correct installation of a newly purchased machine may seem a bit tricky. However, as long as you follow the detailed instructions provided by the manufacturer to guide the operation step by step, there will be no problems. First, confirm that the connection terminals are firmly connected before starting the power-on test run phase, and carefully observe the change trend of various index readings to judge whether the overall health is good or not.

In order for these precision instruments to consistently perform at their best, a regular preventive maintenance program is essential. Simple cleaning dust particle accumulation operation can effectively delay the aging speed; In addition, attention should be paid to check whether the key components are loose, repair and adjust them in time, and return to the initial setting position to continue to maximize the efficiency.