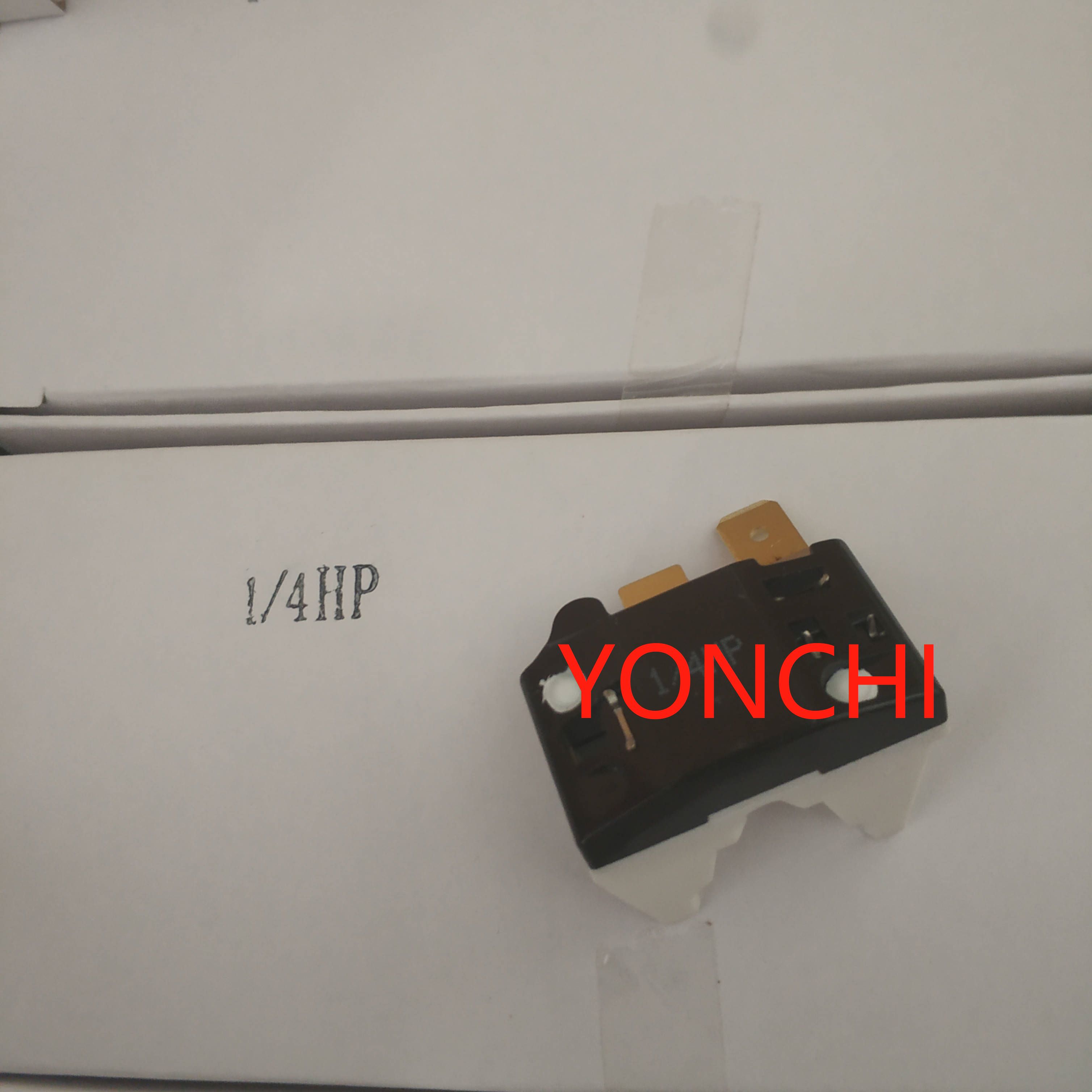

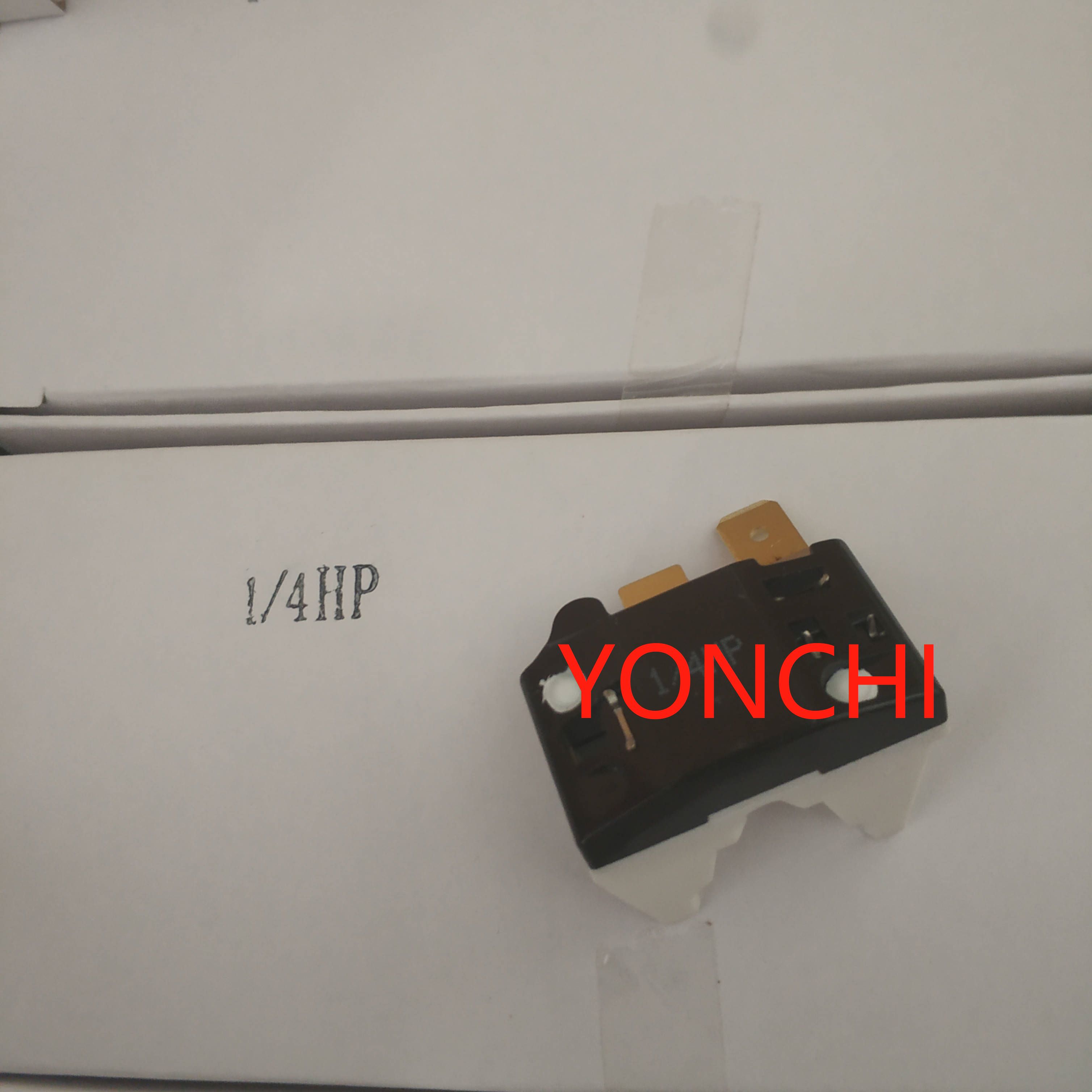

Selected high quality protection relays are designed to provide reliable overload and fault protection for industrial automation systems to ensure efficient and stable operation of equipment.

Ingenuity: Building a Robust and Reliable Protection Core

In the field of industrial automation, protection relays play a vital role. It can not only prevent accidents at critical moments, but also greatly reduce maintenance costs and extend the life of production equipment. Today we will explore the unique design concept and advanced manufacturing process behind this high-quality protection relay.

Multiple protection: against all kinds of potential risks

In order to ensure the normal operation of the electrical equipment in the factory, we need a protective relay that can effectively prevent overload and other electrical faults. This product has an advanced detection mechanism, which can monitor current and voltage changes in real time. Once an abnormality is found, immediately take measures to cut off the power supply to avoid greater losses. Whether it is a short circuit, overheating or leakage, it can be captured and dealt with in time.

Application scenarios: covering a wide range of industrial environments

In view of the powerful function and excellent performance of the protection relay, it has become an essential tool for almost all fields involving electrical equipment management. For example, in the power transmission process, it can ensure that the line is unimpeded; in the machining workshop, it can be used to protect precision machine tools from damage; and in the chemical plant is essential, because it can help avoid equipment failure caused by the security risks.

Installation Guide: Easy and Quick Steps

To make it easy for every user, we have prepared a detailed installation manual. Just follow the instructions to connect the relevant lines, and then turn on the switch to test it. Even people who don't have much knowledge of electricians can do the whole process independently. We also provide online video tutorials for reference to ensure that everyone can quickly learn how to set up and use the product correctly.

Maintenance Secrets: Secrets to Extended Life

Any electronic product needs regular inspection and cleaning to maintain good condition. For this reason, we have summarized some useful maintenance methods for everyone to learn from: first, we should often clean up the dust and impurities on the shell to avoid overheating caused by obstruction of heat dissipation; The second is to regularly replace aging parts such as fuses or terminals to prevent problems such as open circuit. Finally, we should always pay attention to whether there is any abnormal noise or other abnormal conditions, and contact after-sales personnel in time for maintenance.

Case Study: Sharing Stories of Successful Implementation

A large automobile manufacturer in southern China has achieved a significant increase in production line efficiency with the introduction of our protective relays. In the past, due to the old equipment often encountered power outages and restarts and other emergencies, seriously affecting the production schedule. Now these problems are no longer exist, not only save a lot of maintenance costs, but also improve employee satisfaction. This is enough to prove that this product is really trustworthy.

Technical support: the strength of a professional team

In addition to providing quality products, we have an experienced and highly skilled support team ready to answer your questions and provide personalized solutions. Whether it is pre-consultation or post-maintenance, as long as there are any difficulties can contact us for help. In addition, we have conducted a series of webinars aimed at making more people aware of the latest technologies and market dynamics, so as to better use their resources to create value.

Future Outlook: Evolving Technology Trends

As the Internet of Things technology matures, future protection relays will be more intelligent and flexible. They can be networked with other sensors via wireless networks to form a complete monitoring system. This means that you can not only monitor data locally, but also view and adjust parameter settings remotely, greatly improving management and response speed. It is expected that this new type of product will come out soon and gradually replace the traditional model to occupy the dominant position.