In modern society, electricity has become an indispensable part of people's daily life. However, the security risks that follow cannot be ignored. In this context, protective relays, as a key safety device, have gradually become one of the core components of modern electrical systems.

Have you ever wondered how protective relays can accurately detect current anomalies and quickly take measures to prevent accidents? This seemingly simple task actually contains complex technical principles. When the circuit is short-circuited or overloaded, the protective relay will trigger the disconnection of the switch by monitoring the changes of voltage and current in real time, so as to avoid the occurrence of fire or other dangerous events caused by excessive load.

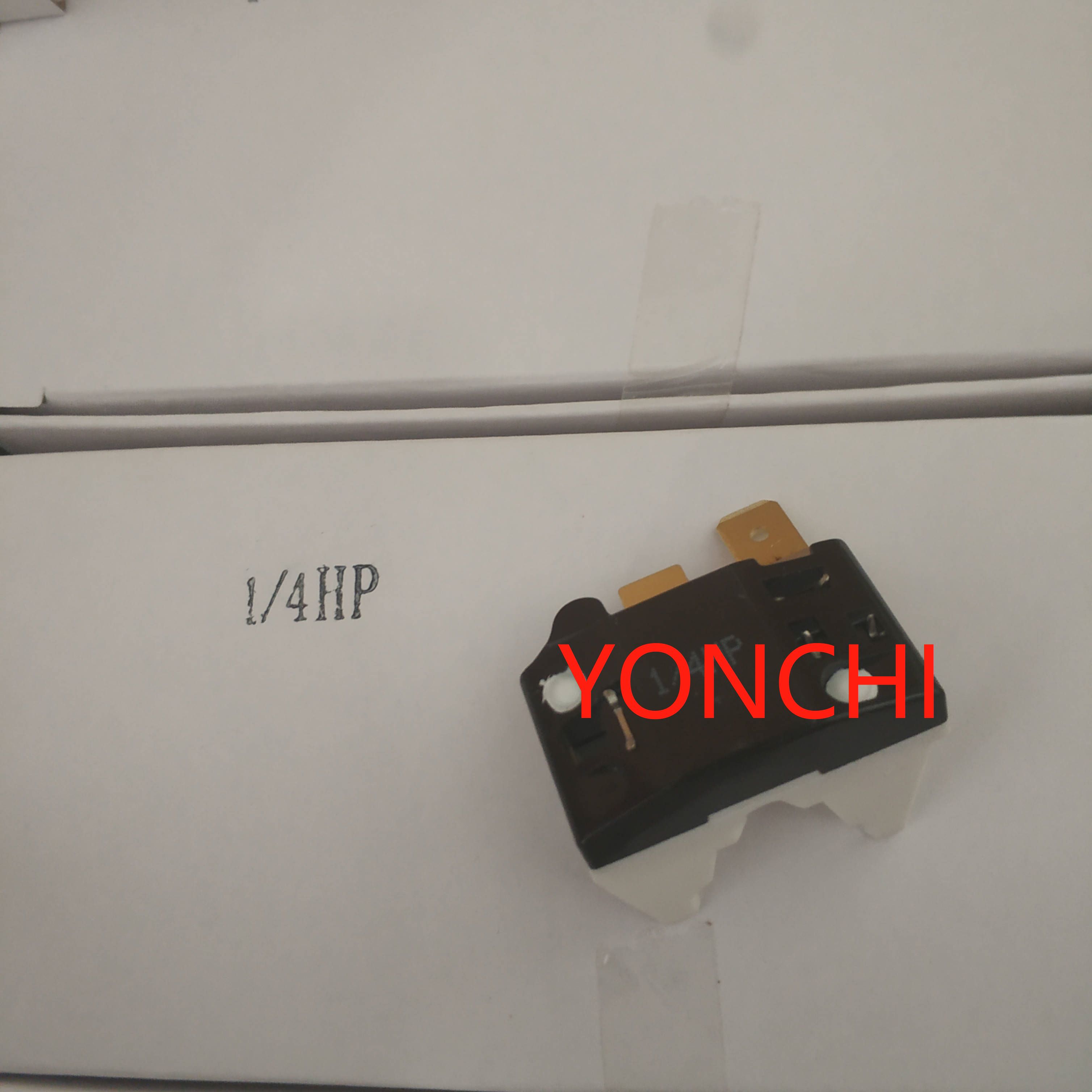

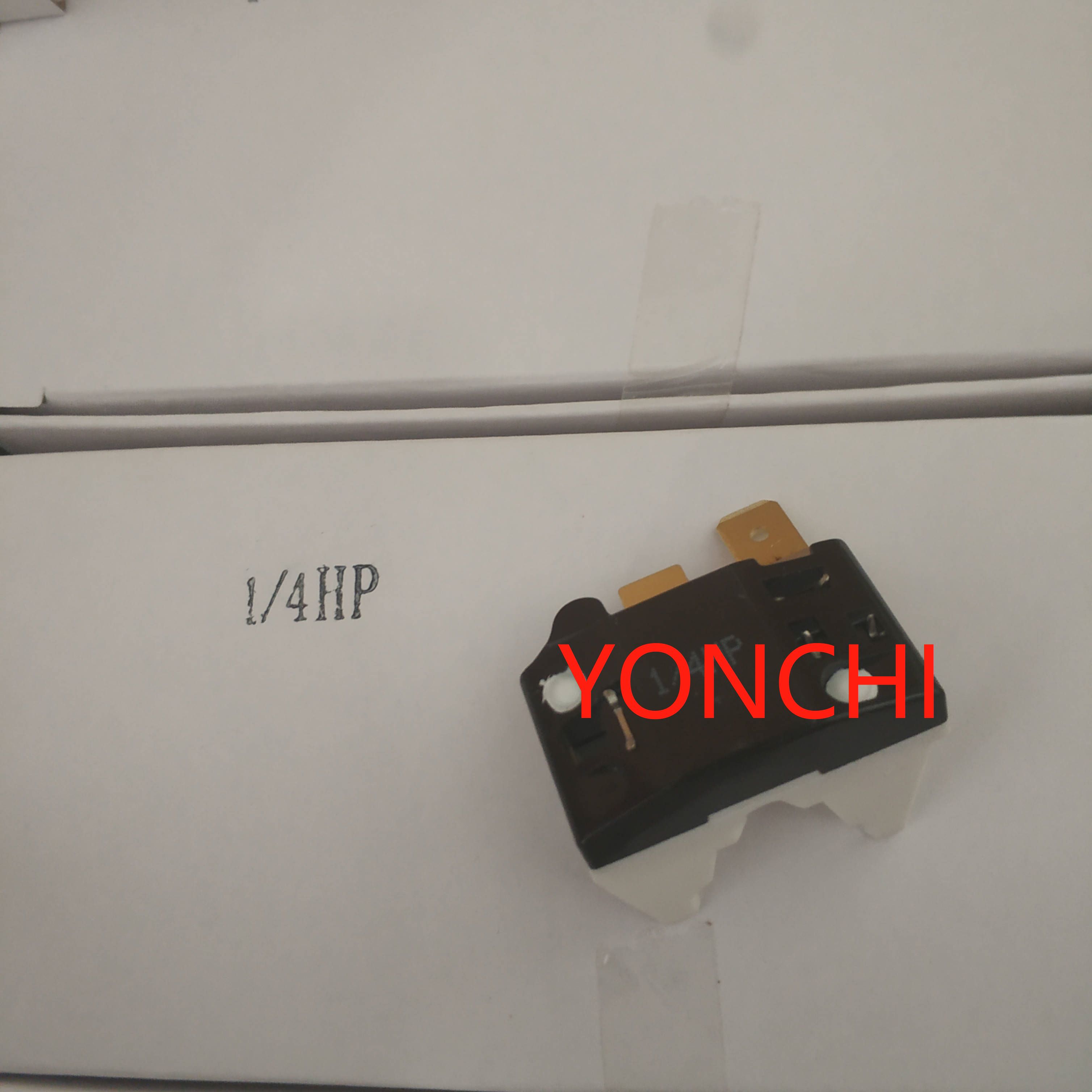

This is because whether it is power equipment running on a large scale on an industrial production line, or ordinary household appliances such as air conditioning and refrigerators at home, you need to rely on this small device for self-protection. Once the fault signal is not captured in time, the consequences are often unimaginable. Therefore, the installation of a reliable protective relay for any size of business and individual users are particularly important.

This is because whether it is power equipment running on a large scale on an industrial production line, or ordinary household appliances such as air conditioning and refrigerators at home, you need to rely on this small device for self-protection. Once the fault signal is not captured in time, the consequences are often unimaginable. Therefore, the installation of a reliable protective relay for any size of business and individual users are particularly important.

So what kind of protective relay can be called the "top" level? The answer is not only limited to the basic elements of high sensitivity and stability, but also includes strong resistance to high temperature and corrosion, compact design and easy integration. In addition, good brands often provide detailed technical documentation and support services to help customers better understand and use their products.

For different application scenarios, it is very important to choose the corresponding protection relay reasonably. For example, models used in distribution boxes in residential buildings generally focus on cost control and ease of maintenance, while in special environments such as chemical plants, professional versions with explosion-proof functions must be selected. Only an accurate grasp of their own needs and close communication with suppliers to find the most appropriate options.

Let's take a look at some successful practical applications! A large manufacturing enterprise has greatly reduced the downtime of the production line while improving the overall work efficiency by introducing the latest generation of digital intelligent protection relays; another commercial complex project has achieved a comprehensive grasp of the status information of thousands of end nodes with the help of a networked remote monitoring platform-these are the intuitive benefits brought by excellent solutions.

In addition to the correct procurement decisions, follow-up good maintenance is also an indispensable part of ensuring long-term stable operation. Regular cleaning of dust and debris to reduce the risk of poor contact and timely calibration of the set value range to prevent drift error accumulation are very effective means. In addition, it is worth noting that some old models may face the problem of production and elimination of accessories over time, so it is also necessary to make an upgrade plan in advance.

Looking to the future, with the advancement of Internet of Things technology and artificial intelligence algorithms, a new generation of intelligent protection relays is gradually moving towards the foreground. They can not only independently complete regular judgment processing tasks, but also seamlessly connect with other automated control systems to form a more complete overall defense system. It can be predicted that in the near future, such high-tech achievements will benefit more fields and bring greater value creation space.